Impact Modifier ADX-600

Application

● PVC Profiles

● PVC Pipes

● PVC Pipe Fittings

● PVC Parts

● Other UPVC application

Features

ADX-600 impact modifier is a free-flowing powder.

| Property | Index | Unit |

| Appearance | White Powder | |

| Bulk Density | 0.4-0.6 | g/cm3 |

| Volatile Matter | <1.0 | % |

| 20 Mesh Screening | >99 | % |

*The index just represents typical results which are not considered as a specification.

Key Attributes

1.Excellent impact resistance

2.Good weather resistance

3.High plasticizing efficiency

4.Low post-extrusion shrinkage or reversion

5.Good processing performance and high gloss

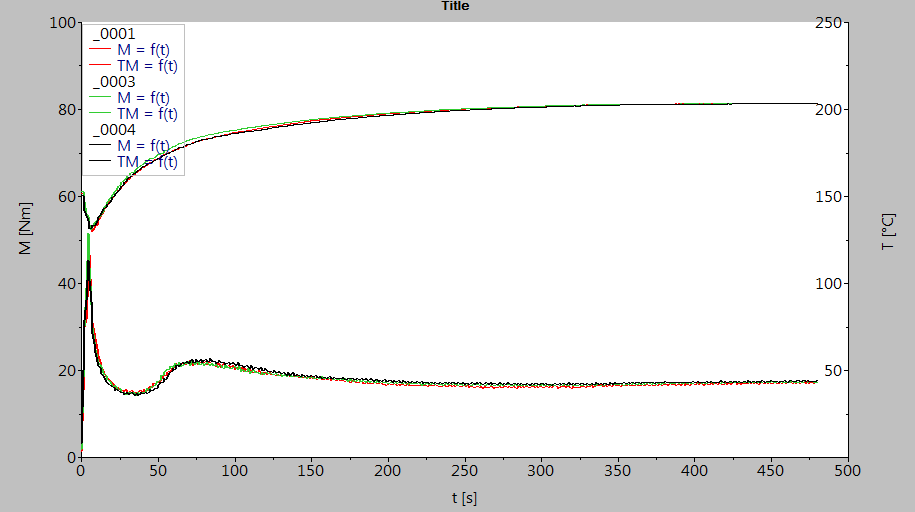

Rheology and Processing

ADX-600 impact modifier show faster fusion features than competitive products, which can be achieved economically by reducing the dosage of processing aids and internal lubricants in the formulation.

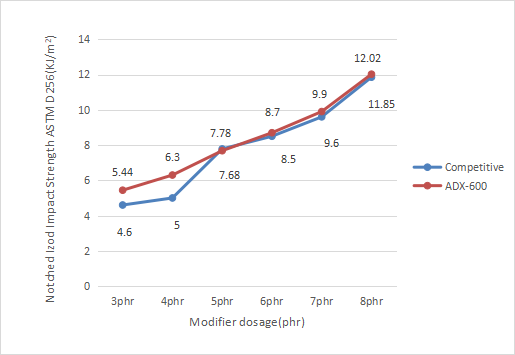

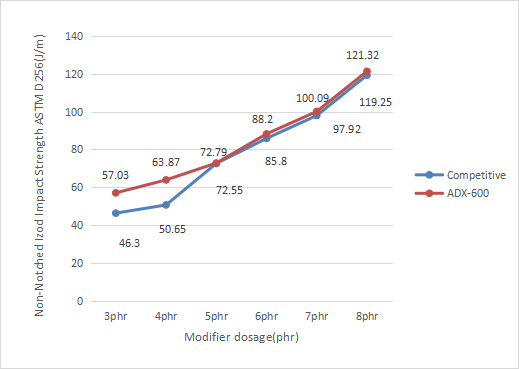

Impact Strength

ADX-600 impact modifier has good impact improvement at room temperature and 0°C.

The ADX-600 is far more efficient than competitive products.

Examples of Formula Use

| Name | Organotin Heat Stabilizer(HTM2010) | Calcium Stearate | Titanium Dioxide | Calcium Carbonate | PVC-1000 | PE Wax | OPE | ADX-600 |

| Dosage(g) | 2.0 | 0.7 | 4.0 | 5.0 | 100 | 0.6 | 0.2 | 6.0 |

Tensile Data ASTM D638

| Name | Modifier Dosage | Tensile Modules of Elasticity(MPa) | Elongation at Break(%) | Tensile Strength(MPa) |

| Competitive | 6phr | 2565.35 | 27 | 43.62 |

| ADX-600 | 6phr | 2546.38 | 28 | 43.83 |

Bending Data ASTM D790

| Name | Modifier Dosage | Flexural Modulus | Bending Strength(MPa) |

| Competitive | 6phr | 2509.3 | 65.03 |

| ADX-600 | 6phr | 2561.1 | 67.3 |

Rheology

| Name | Organotin Heat Stabilizer(HTM2010) | Calcium Stearate | Titanium Dioxide |

Calcium Carbonate |

PVC-1000 | PE Wax | OPE | ADX-600 |

| Dosage(g) | 2.0 | 0.7 | 4.0 | 5.0 | 100 | 0.6 | 0.2 | 5.0 |

Modifier Dosage 5phr

Black curve: ADX-600

Red curve: Competitive (foreign similar products)

Weatherability

Initial Color: 1(Competitive 6phr)--(L 91.9 a -12 b +8.7)

2(ADX-600 6phr)--(L 92.9 a -12.4 b +8.8)

| Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | ||||||

| △a | △b | △a | △b | △a | △b | △a | △b | △a | △b | |

| 1(Competitive 6phr) | 0.0 | 0.3 | 0.0 | 0.3 | 0.0 | 0.5 | 0.0 | 0.6 | 0.1 | 0.6 |

| 2(ADX-600 6phr) | 0.2 | -0.2 | 0.1 | -0.1 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 |

| Day 6 | Day 7 | Day 8 | Day 9 | Day 10 | ||||||

| △a | △b | △a | △b | △a | △b | △a | △b | △a | △b | |

| 1(Competitive 6phr) | -0.1 | 0.8 | -0.2 | 1.2 | -0.2 | 1.3 | -0.1 | 1.6 | 0.0 | 2.1 |

| 2(ADX-600 6phr) | -0.1 | 0.4 | 0.0 | 0.6 | 0.0 | 0.7 | 0.0 | 0.8 | 0.0 | 1.0 |

In the above table,

△ a represents the change value of red and green. △a is a positive value, indicating that the test piece becomes red. △a is a negative value, indicating that the test piece becomes green.

△ b represents the change value of yellow and blue. △b is a positive value, indicating that the test piece becomes yellow. △b is a negative value, indicating that the test piece becomes blue.

This test mainly referred to the change of △b value. The larger the positive direction of △ b value, the yellower the sample.

Experimental Conclusion: It can be clearly seen from the above table that the weather resistance of ADX-600 is better than competitive.

Experimental Equipment: Colorimeter(Konica Minolta CR-10), QUV(America Q-LAB)